- +1 (212)-695-1962

- info@elementskit.com

- 463 7th Ave, NY 10018, USA

Industrial Strainer - Y Type | Basket Strainers in Ahmedabad | All-Type Strainer Solutions

We are a robust and trusted organization with a legacy of excellence in providing high-quality industrial strainers and filtration solutions. With decades of combined experience, we specialize in meeting the diverse needs of key industries across the country, including Oil & Gas, Power, Pharmaceuticals, Steel Mills, Pulp & Paper, Fertilizers, Chemicals, Cement, Petrochemical Refineries, Nuclear, Shipbuilding, and more.

Our focus is on delivering simple yet effective solutions tailored to the unique requirements of each industry. The design and construction of our strainers and valves are meticulously crafted by experts with extensive professional experience. This ensures that our products are not only highly effective but also cost-efficient, providing long-term value to our clients.

Industrial Strainer - Y Type Strainers Products

125

Class 125 Cast Iron Screwed End Simplex Basket Strainers

125-B

Class 125 Cast Aluminum Bronze Screwed End Simplex Basket Strainers

125-CS

Class 150 Cast Carbon Steel Screwed End Simplex Basket Strainers

125

Class 125 Cast Iron Screwed End Simplex Basket Strainers

125-B

Class 125 Cast Aluminum Bronze Screwed End Simplex Basket Strainers

125-CS

Class 150 Cast Carbon Steel Screwed End Simplex Basket Strainers

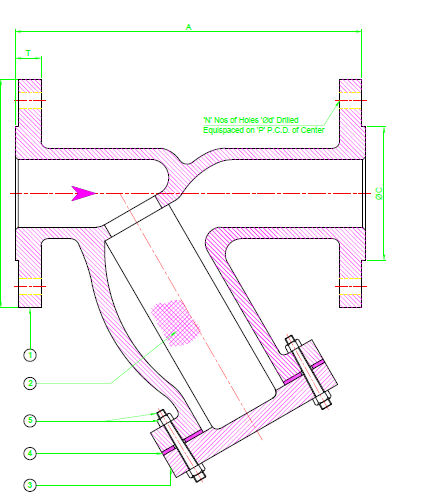

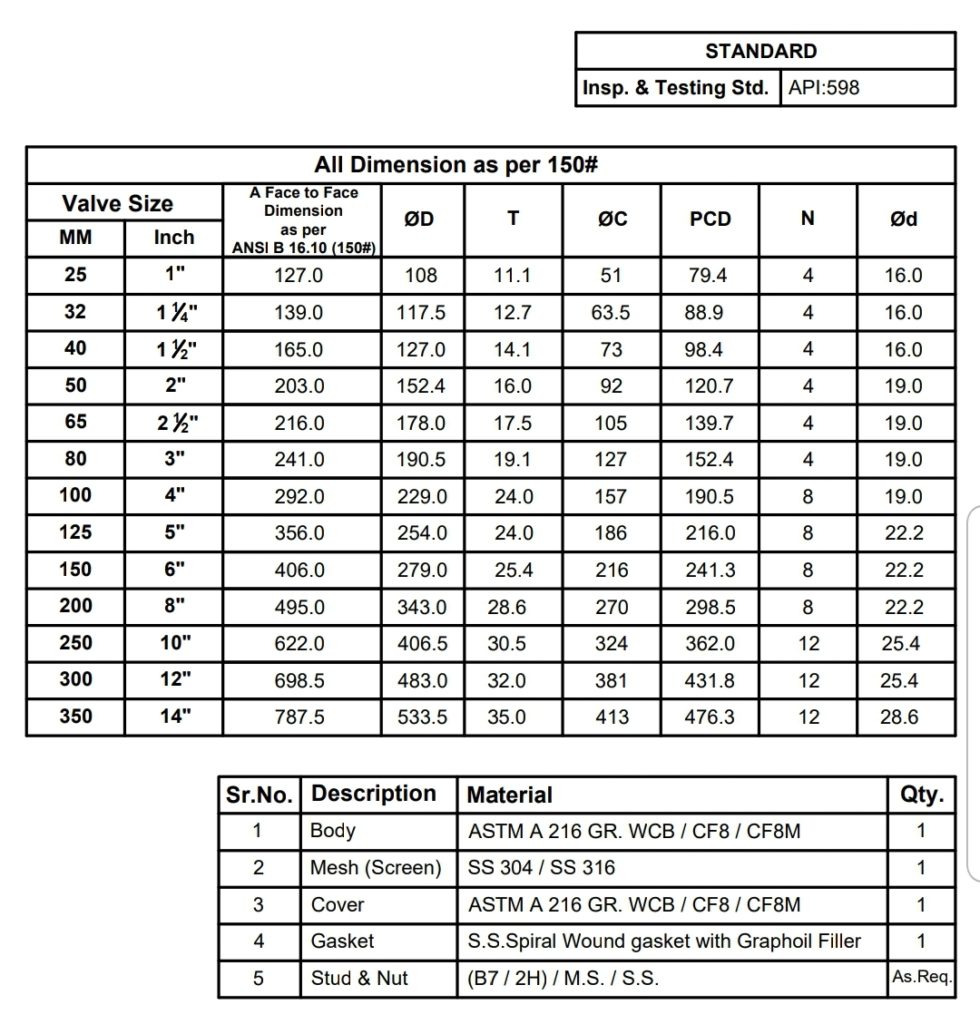

Industrial Strainer – Y Type Technical Diagram

Why Choose Our Strainers?

- High-Quality Materials: Built to withstand demanding industrial environments.

-

Versatility: Suitable for a wide range of applications and industries.

-

Efficient Filtration: Effectively captures and holds solid particles to protect machinery and maintain fluid purity.

-

Durable Design: Engineered for long-lasting performance and reliability.

-

Global Reach: Exported to numerous countries, ensuring international quality standards.

Whether you need Y-type strainers, basket strainers, or other filtration solutions, we provide the best products tailored to meet your industrial needs. Trust us for high-quality strainers that deliver exceptional performance and reliability in Ahmedabad and beyond.

Industries We Serve

Paper industries

Pharmaceuticals Industries

Petrochemical Industries

Power Industries

Waste Water Industries

Areas We Serve

We Serve All Over India :- Ahmedabad | Mumbai | Surat | Delhi | Rajasthan | Tamilnadu | Hyderabad | Banglore | Pune | Kerala | Assam | Haryana | Punjab | Madhya Pradesh | Telangana | Tumkur | Jamnagar | Chiplun | Khed | Lucknow | Kanpur | Thane | Bhopal | Dibrugarh | Angul | Gwalior | Coimbatore | Goa | Kharagpur | Nashik | Bareilly | Durgapur | Varanasi | Raigad | Mahad | Mangaon | Raipur | Cochin | Ludhiana | Panipat | Chakan | Chennai | Kolkata | Noida | Panna | Jaipur | Agra | Bhagalpur | Jamshedpur | Bhilai | Salem | Panvel | Bhiwandi | Tiruppur | Sivakasi | Thiruvananthapuram | Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Peenya | Moradabad | Indore | Visakhapatnam | Trivandrum | Pimpri-Chinchwad | Channapatna | Roha | Ratnagiri | Haldia | Rourkela | Pithampur | Kannur | Nagpur | Rudrapur |