Industrial strainers are widely used in both industrial settings and residential applications to eliminate impurities and solid materials from process flows. Specifically designed for various industrial tasks, these strainers play a crucial role in ensuring the integrity of fluid systems.

Functionality of Industrial Strainers

Similar to other filtration devices, industrial strainers facilitate coarse filtration of fluids in large pipelines. They typically feature a wire mesh of varying sizes, supported by a perforated sheet. The mesh openings are designed to be smaller than the particles they aim to capture, allowing fluid to pass through while retaining unwanted solids.

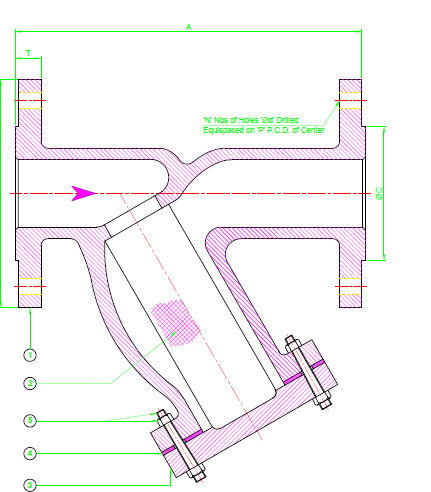

Industrial Strainer – Y Type Technical Diagram

y type strainer technical diagram

y type strainer technical diagram

We can supply different types of industrial strainer like Industrial Basket Strainer, Industrial Conical Strainer, Industrial Oil Strainer, Industrial Mesh Strainer.

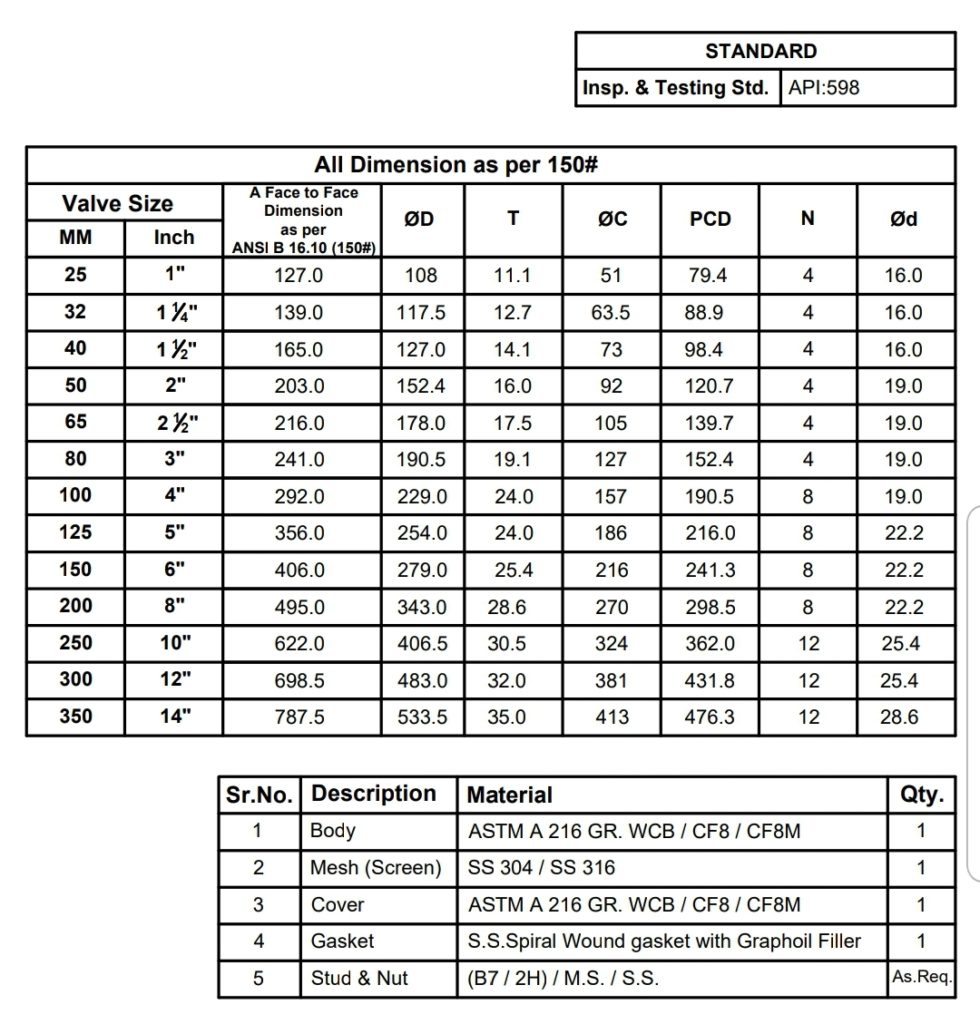

150#

We can customize all types of industrial Strainer such as basket type strainer, Y type strainer, Pot type strainer, Oil Basket Strainer and all different pipeline strainers.

We can send customized Industrial Strainer Images with necessary technical details to ease your process. Under 24 hours we are able to provide all the industrial strainer prices to you.

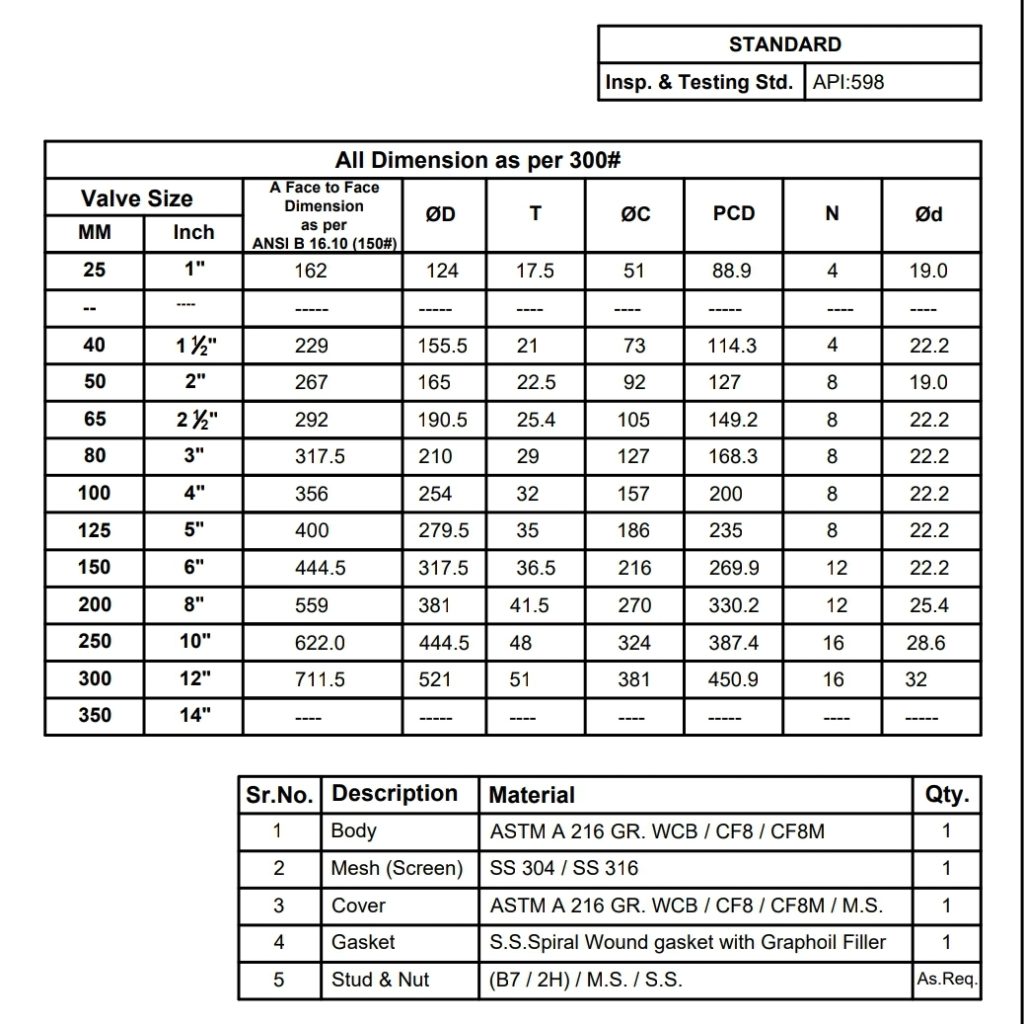

300#

Applications of Y Type Strainers

Y strainers are particularly beneficial in industries that require ongoing protection against debris. Their most common use is in steam applications, where their design allows them to endure high pressure. In liquid applications, Y strainers are essential for preventing sand and gravel from causing damage or blockages in water handling systems.These strainers are also effective in natural gas and air applications, where high pressure and temperature conditions are prevalent. The versatility of Y strainers means that their construction materials must be tailored to specific applications; for instance, chrome-moly steel is recommended for high-temperature steam or gas environments.

Industrial Basket Strainers

Basket strainers utilize a perforated or wire mesh screen within a vertically oriented chamber to mechanically filter out particles from liquids in commercial and industrial piping systems. They offer greater debris capacity and lower pressure drops compared to Y strainers, making them suitable for liquid applications.Common materials for basket strainers include iron, carbon steel, bronze, and stainless steel. Iron is favored for its cost-effectiveness and corrosion resistance, while carbon steel is preferred in oil and petrochemical sectors due to its durability under high temperatures. Bronze offers better heat resistance than iron but has limitations in temperature range, whereas stainless steel is ideal for industries where corrosion is a significant concern.Basket strainers come with various end connections such as threaded, flanged, and welded options. Standard screens are available for water, oil, gas, or steam services but can be customized based on specific needs.