Industrial strainers are essential tools utilized in various industrial and residential environments to remove impurities and solid particles from fluid flows. These strainers are specifically engineered for multiple industrial applications, playing a vital role in maintaining the integrity of fluid systems.

Functionality of Industrial Strainers

Industrial strainers serve as coarse filtration devices within large pipelines. They typically consist of a wire mesh with different opening sizes, supported by a perforated sheet. The mesh openings are smaller than the particles intended for capture, allowing fluids to flow through while retaining unwanted solids.

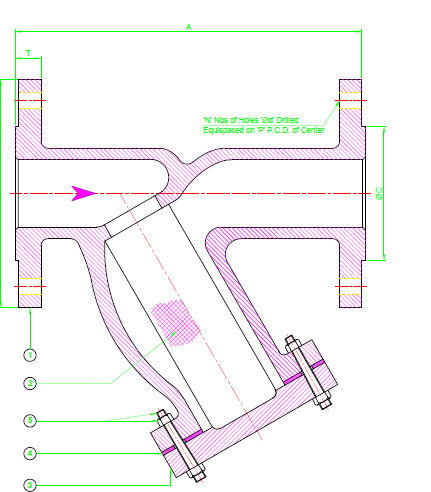

Industrial Strainer – Y Type Technical Diagram

y type strainer technical diagram

y type strainer technical diagram

We can supply different types of industrial strainer like Industrial Basket Strainer, Industrial Conical Strainer, Industrial Oil Strainer, Industrial Mesh Strainer.

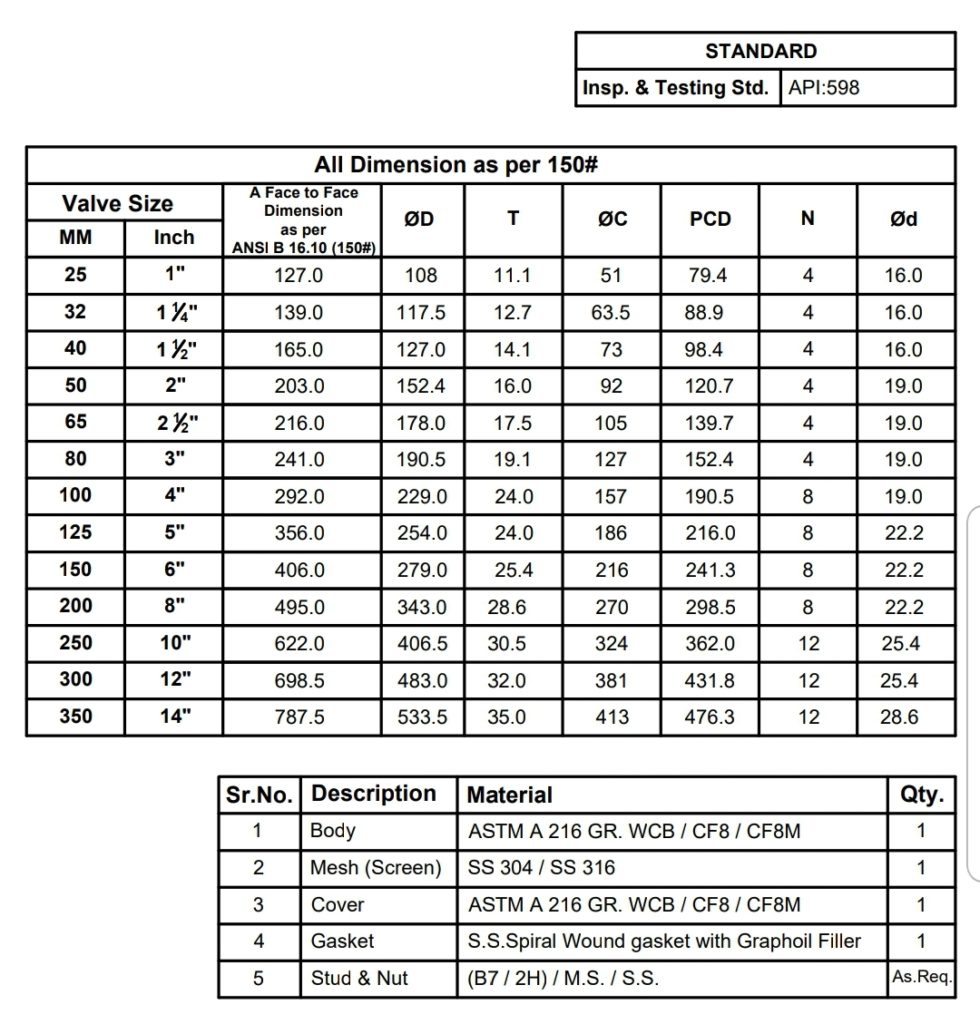

150#

Applications of Y Type Strainers

Y type strainers are particularly useful in industries that require continuous protection against debris. They are commonly employed in steam applications due to their ability to withstand high pressure. In liquid applications, Y strainers help prevent damage or blockages caused by sand and gravel in water handling systems. Additionally, they are effective in natural gas and air applications where high pressure and temperature conditions exist. The materials used for constructing Y strainers must be tailored to specific applications; for example, chrome-moly steel is recommended for high-temperature steam or gas environments.

Industrial Basket Strainers

Basket strainers feature a perforated or wire mesh screen within a vertically oriented chamber that mechanically filters particles from liquids in commercial and industrial piping systems. They provide higher debris capacity and lower pressure drops compared to Y strainers, making them suitable for liquid applications. Common materials for basket strainers include iron, carbon steel, bronze, and stainless steel. Iron is favored for its cost-effectiveness and corrosion resistance, while carbon steel is preferred in the oil and petrochemical sectors due to its durability under high temperatures. Bronze offers better heat resistance than iron but has limitations on temperature range, whereas stainless steel is ideal for industries where corrosion is a significant concern. Basket strainers are available with various end connections such as threaded, flanged, and welded options, with standard screens offered for water, oil, gas, or steam services that can be customized based on specific requirements.