What is a Fabricated Strainer, and how does it work?

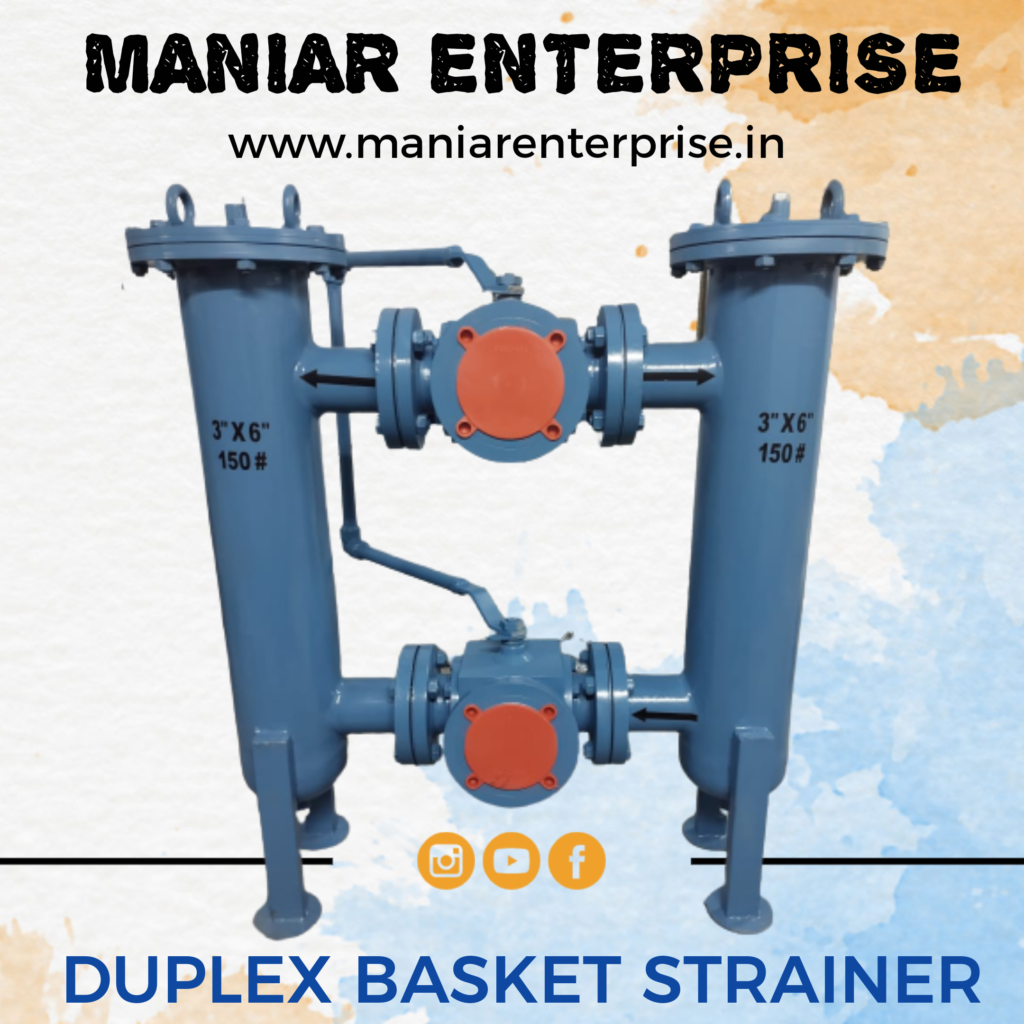

A fabricated strainer is a device with pores, similar to a sieve, for separating solids from liquids.

As the liquid flows through it to other destinations, it preserves any solid pieces that may be in the fluid.

It usually works as a filter, sieving and blocking solid material that you won’t need later on.

Manufacturers often use fabricated strainers to match the industrial requirements of different applications.

It’s because industrial uses differ, and a conventional strainer may not fit all of them.

Why Do Pipelines Need Fabricated Strainers?

A fabricated strainer will function similarly to a standard strainer, but with a few tweaks to boost its efficiency. You will provide the manufacturer with precise criteria and parameters in order for them to customize or fabricate a strainer for you. The device will then be used to trap foreign solid materials in flowing fluids, such as sediments and rust.

To keep solid materials out, it works best with perforated metals, wire mesh, and wedge wires. Pipe systems, sprinkler heads, pumps, valves, turbines, meters, and nozzles will all be protected from solid contaminants. Because the gadgets are expensive to purchase, they must be protected from solid debris that could cause damage.

It will also boost the productivity of the machines that it is shielding from solid matter harm. It means that the machines will always work without being interrupted by solid material that could damage them. In the end, it will make a substantial contribution to the whole system’s productivity and efficiency.

You’ll save a lot of money and time as well, especially if you don’t have to maintain the devices. Keeping solid matter out of the machines will help them last longer. You will spend the least amount of money on maintenance in the long term, and you will save time.

Apart from that, you can use it to resolve application difficulties such as:

- Space restrictions

- Special Pipe Connections are one-of-a-kind

- Several opening systems are available

- Cast metal modifications

- Clients have a lot of options to pick from, especially when it comes to having custom-made strainers.

You have a variety of alternatives to pick from, including:

- Strainers must be resized to meet the flow process’s requirements.

- By developing one-of-a-kind covers, we can provide a pleasant and easy-to-maintain them.

- When you need to employ a strainer for specific uses, such as manufacturing, you’ll require a fabricated strainer.

- You’ll take customization seriously at this point and specify the type and design you want.

- Take notice of the temperature requirements, the application’s pressure systems, and the marketability of these designs.

Material for Fabricated Strainers

The term fabrication encompasses a wide range of modifications that can be applied to a strainer.

Fabricated strainers have been manufactured for a long time utilising various materials.

It implies you have complete freedom in selecting the type of material that best suits your needs.

Stainless steel, copper, brass, aluminum, cast iron, and carbon steel are the most prevalent materials used in strainer fabrication.

Fabricated Strainers made of stainless steel

This is a type of manufactured strainer that is made of stainless steel as the primary material.

Manufacturers will employ a variety of stainless steels, including SS 304 , SS 316, SS 316Ti and SS 321 among others.

This type of steel is preferred by manufacturers because it resists corrosion and improves the performance of the constructed strainer.

Aside from corrosion resistance, stainless steel possesses the following characteristics that manufacturers want.

- It is extremely durable and has a high cryogenic strength.

- Even while being used, it has a very high rate of hardening.

- It is quite beneficial in a wide range of temperatures, and it may even be used at extremely high temperatures.

- Properties of high ductility

- Higher hardness and strength, as well as the ability to bear extreme pressure.

- It has a more appealing appearance.

- It takes extremely minimal upkeep, which saves both time and money.

These characteristics make it the most sought-after materials for strainer fabrication. It can also work in diverse pressure and temperature extremes without causing damage.

Fabricated Strainers made of copper

Manufacturers had the advantage of experimenting with and discovering new materials for strainer fabrication, such as copper.

It is comparable to other materials, but it has its own distinct characteristics that you should consider.

Despite its good heat and electrical conductivity capabilities, it is an important material for fabricating strainers for the following reasons:

- It has the ability to resist corrosion and hence does not rust, making it an ideal material.

- Has antibacterial qualities, making it suitable for usage in residential settings.

- It’s soft and easy to combine with different materials.

- It has ductile qualities.

- It’s a robust substance that can tolerate heat and pressure.

- It isn’t a magnet.

- It’s also incredibly elegant and will help to boost the image of the strainers that have been manufactured.

- It’s easy to alloy, and it can be recycled for different uses.

- Aside from the features listed above, it is also a tough substance.

Aluminum fabricated strainers

The other material that manufacturers like to utilize in the fabrication of strainers is aluminum. Aluminum is a chemically and physically similar metal to other metals that can be used to build strainers. It possesses qualities that can be manipulated, such as melting and casting, and it responds well to pressure moulding.

Aluminum has a number of qualities that make it ideal for strainer fabrication :

- It’s a light material that saves energy and weight while enhancing load capacity.

- The quality of the constituent alloys can be improved to make it stronger.

- Because of its corrosion resistance, it is one of the best materials for usage in rust-prone areas.

- Aluminum’s reflective properties make it a better material for heat reflection.

- It has a low melting temperature and is ductile, making it an ideal material for strainer manufacturing.

- It is impermeable, which means that no substance, even smell, can pass through it.

Brass fabricated strainers

Brass is a material that has come as a result of combining a wide range of zinc and copper alloys. Brass is a generic name for a metal that was created by mixing two different types of metals. They have a lot of characteristics that make them ideal for strainer manufacture.

Brass has the following properties:

- It has a high tensile strength, which makes it resistant to breakage.

- Machinability

- Ductility

- High tear and wear resistance

- It can tolerate both low and high pressure systems.

- It’s quite appealing because of the colours.

- It is safe to use because of its antimicrobial characteristics.

- It’s also anti-corrosion, which means it won’t rust.

- You have the option of recycling the mate as well.

Strainers made of cast iron

Fabricated strainers are likewise the result of casting iron being fabricated to create a flawless device. It is a carbon-iron alloy that is particularly popular due to its inexpensive cost.

Cast iron strainers have the following characteristics when manufactured:

- It has a good corrosion resistance.

- It can’t be manufactured as hard as steel because it’s neither ductile nor malleable.

- It exhibits a granular or crystalline fracture and has an extremely high melting point.

- The alloy’s physical qualities are overly reliant on its carbon concentration.